Introduction

Robotic arms are mechanical arms that can be programmed to carry out complex tasks, such as welding, painting, or assembly. They are often used in industrial settings, but they can also be used for educational, research, and hobbyist purposes. Building your own robotic arm is a great way to learn about robotics, gain hands-on experience with technology, and have fun.

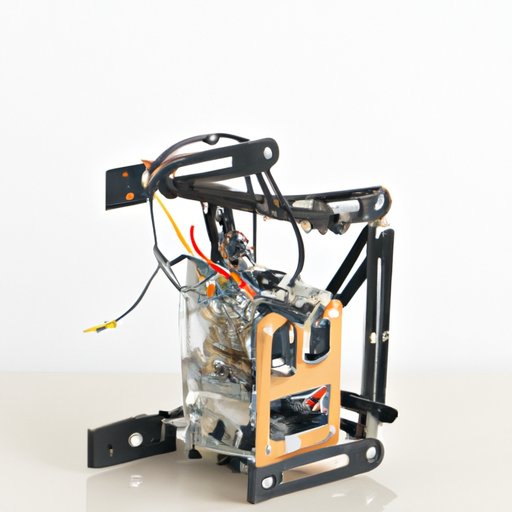

What is a Robotic Arm?

A robotic arm is an electromechanical device that consists of several joints and links. It is designed to move in multiple directions and angles, allowing it to perform precise and repeatable tasks. The arm has multiple degrees of freedom that allow it to reach various positions and orientations. In addition, the arm can be programmed to carry out specific tasks, such as pick and place, welding, painting, and assembly.

Benefits of Building Your Own Robotic Arm

Building your own robotic arm is a great way to gain hands-on experience with robotics and technology. It can help you learn about the fundamentals of robotics, such as mechanics, electronics, and programming. Additionally, building a robotic arm is a fun project that can be done with friends or family. It is a great way to bond and learn together.

Step-by-Step Guide to Building Your Own Robotic Arm

Building a robotic arm is a complex process that requires knowledge of robotics, electronics, and programming. However, with the right tools and knowledge, anyone can build their own robotic arm. This guide will provide a step-by-step approach to building your own robotic arm.

Choosing the Right Components

The first step in building your own robotic arm is to choose the right components. You will need motors, servos, electronics, a frame, and structure. You should consider the type of robotic arm you want to build and select components that are suitable for the task. For example, if you want to build a robotic arm that can lift heavy objects, you will need strong motors and a sturdy frame.

Designing the Arm

Once you have chosen the components, you can begin designing the arm. You will need to decide on the number of joints, the length of each joint, and the type of movement you want the arm to be able to perform. Additionally, you will need to design the frame and structure of the arm. This includes deciding on the size and shape of the frame, as well as the materials you will use to construct it.

Assembling the Arm

Once you have designed the arm, you can begin assembling it. This involves connecting the motors, servos, and other components to the frame and structure. You will also need to connect the electronics, such as the power source, control board, and sensors. This is a time consuming process, so be sure to take your time and double check all connections.

Programming the Arm

Once the arm is assembled, you can begin programming it. Programming the arm involves writing code that will control the motors and servos. This code can be written in any programming language, such as C++ or Python. Additionally, many robotic arms come with software that makes programming easier. This software can be used to create programs that control the arm’s movements, such as pick and place, welding, painting, and assembly.

Understanding the Components Needed for a Robotic Arm Build

Before beginning to build a robotic arm, it is important to understand the components that are needed. The components needed depend on the type of robotic arm you are building and the tasks it will be performing. Here is a breakdown of the components needed for a robotic arm build.

Motors

Motors are the components that provide power to the robotic arm. Motors are typically electric motors, but they can also be hydraulic or pneumatic. Motors come in a variety of sizes and power outputs, so it is important to choose the right motor for your application.

Servos

Servos are the components that control the movement of the robotic arm. Servos are small motors that are connected to a control board. They are used to move the arm in a specific direction, angle, or speed. Servos come in a variety of sizes and torque ratings, so it is important to choose the right servo for your application.

Electronics

The electronics are the components that provide power and control to the robotic arm. This includes the power source, control board, and sensors. The power source can be a battery or an AC outlet, while the control board is used to send signals to the motors and servos. Sensors are used to detect the position and orientation of the arm.

Frame and Structure

The frame and structure are the components that provide support and stability to the robotic arm. The frame and structure can be made from a variety of materials, such as aluminum, steel, plastic, or wood. The frame and structure must be designed to support the weight of the arm and its components.

Exploring the Design Options for Robotic Arms

When designing a robotic arm, there are several factors to consider. Here is an overview of the types of robotic arms and design considerations.

Types of Robotic Arms

Robotic arms come in a variety of shapes and sizes. The most common type is the articulated arm, which has multiple joints and links. Other types of robotic arms include the scara arm, delta arm, and gantry arm. Each type of robotic arm has different capabilities and applications.

Design Considerations

When designing a robotic arm, there are several factors to consider. These include the size and weight of the arm, the number of degrees of freedom, the type of movement required, and the environment in which the arm will be operating. Additionally, you should consider the materials you will use to construct the arm and the type of motors and servos you will need.

Tips for Assembling and Programming Your Robotic Arm

Assembly and programming are two of the most important steps in building a robotic arm. Here are some tips for assembling and programming your robotic arm.

Assembly Tips

When assembling your robotic arm, it is important to be patient and take your time. Make sure all connections are secure and double check them before powering up the arm. Additionally, refer to the manufacturer’s instructions for any additional tips.

Programming Tips

When programming your robotic arm, it is important to think through the code before writing it. Make sure the code is efficient and easy to read. Additionally, use comments to explain the code and break it into smaller sections. Finally, test the code thoroughly before running it on the arm.

What Can You Do with a Robotic Arm?

Robotic arms are versatile machines that can be used for a variety of tasks. Here is an overview of the common uses and specialized uses of robotic arms.

Common Uses

Robotic arms are commonly used in industrial settings, such as manufacturing and assembly. They can be used to automate repetitive tasks, such as welding, painting, and pick and place. Additionally, robotic arms can be used for research purposes, such as testing new technologies.

Specialized Uses

Robotic arms can also be used for more specialized tasks, such as surgical procedures, material handling, and food preparation. Additionally, they can be used in education and entertainment, such as teaching students about robotics and providing interactive experiences at museums and amusement parks.

Troubleshooting Common Problems in Robotic Arm Construction

Building a robotic arm can be a challenging process. Here is an overview of some of the common problems that may arise and how to troubleshoot them.

Common Issues

Some of the most common issues with robotic arm construction include incorrect wiring, faulty components, and programming errors. Additionally, the arm may not move correctly due to mechanical issues, such as loose screws or bent components.

Troubleshooting Solutions

To troubleshoot these issues, it is important to check all connections and components. Additionally, you should refer to the manufacturer’s instructions and double check the programming code. If the problem persists, it may be necessary to replace the faulty component or seek professional help.

Conclusion

Building a robotic arm is a complex process that requires knowledge of robotics, electronics, and programming. However, with the right tools and knowledge, anyone can build their own robotic arm. This guide provided a step-by-step approach to building your own robotic arm, including choosing the right components, designing the arm, assembling the arm, programming the arm, and troubleshooting common problems. With a little patience and dedication, anyone can build a robotic arm and reap the rewards of this rewarding and educational project.

(Note: Is this article not meeting your expectations? Do you have knowledge or insights to share? Unlock new opportunities and expand your reach by joining our authors team. Click Registration to join us and share your expertise with our readers.)