Introduction

Gauge size is a numerical system used to measure the diameter of wires, pipes, and other round objects. It is an important factor to consider when manufacturing products, and understanding how it works is essential for anyone who works with wire or manufactures products. This article will provide a comprehensive guide to understanding and measuring gauge size, as well as tips for choosing the right gauge size for your project.

Explaining Gauge Sizes and How They Work

What is a gauge? A gauge is a numerical system that measures the diameter of wires, pipes, and other round objects. The larger the gauge number, the smaller the diameter of the object. For example, a 12-gauge wire has a smaller diameter than a 10-gauge wire. The relationship between wire diameter and gauge size is inverse; as the gauge size increases, the wire diameter decreases.

Gauge size calculation is based on the cross-sectional area of the wire. The formula for calculating the gauge size of a wire is as follows: Gauge = (Cross-Sectional Area/π)^0.5. In other words, the gauge size is equal to the square root of the cross-sectional area divided by pi.

A Guide to Understanding the Basics of Gauge Size

Gauge sizes vary depending on the material being measured. For example, steel wires are typically measured in American Wire Gauge (AWG), while copper wires are typically measured in Standard Wire Gauge (SWG). There are several types of gauge sizes, including American Wire Gauge (AWG), Standard Wire Gauge (SWG), and Birmingham Wire Gauge (BWG). Each type of gauge size has its own range of values, so it is important to know which type of gauge size is being used when measuring an object.

Gauge sizes are commonly used in manufacturing and construction. They are used to measure the thickness of sheet metal, wire, tubing, and other materials. They are also used to measure the size of screws, bolts, and other fasteners. Gauge sizes can also be used to measure the size of holes, such as those used for rivets and screws.

What You Need to Know About Gauge Size

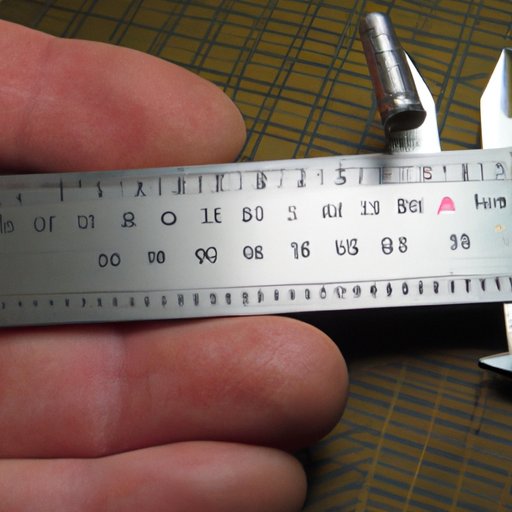

There are several measurement techniques for gauge size. The most common technique is to use a micrometer, which is a precision instrument that measures the diameter of objects. Other measurement techniques include using calipers, rulers, and gauges. It is important to choose the right measurement technique for your application, as each technique has its own strengths and weaknesses.

When choosing the right gauge size for your project, there are several factors to consider. These include the type of material being measured, the accuracy required, and the cost of the tools needed to measure the gauge size. Additionally, it is important to consider the safety implications of using the wrong gauge size, as incorrect measurements can lead to accidents or malfunctions.

An Overview of Gauge Size and Its Uses

Different types of gauges have different uses. For example, American Wire Gauge (AWG) is commonly used for measuring electrical wiring, while Standard Wire Gauge (SWG) is commonly used for measuring copper and brass wires. Birmingham Wire Gauge (BWG) is often used for measuring sheet metal, while Screw Gauge (SG) is used for measuring the size of screws and bolts.

Using gauge sizes in manufacturing offers several benefits. Gauge sizes allow manufacturers to quickly and accurately measure the thickness of materials, which helps them to produce products of consistent quality. Additionally, using gauge sizes can help manufacturers save time and money, as they do not need to purchase multiple tools for measuring different materials.

How to Measure Gauge Size for Your Project

Measuring gauge size requires specific tools, such as a micrometer or caliper. It is important to select the right tool for the job, as each tool has its own advantages and disadvantages. Additionally, it is important to use the correct technique when measuring gauge size, as incorrect measurements can lead to inaccurate results.

The steps for measuring gauge size are as follows: 1) Select the appropriate tool for measuring the gauge size. 2) Measure the diameter of the object. 3) Calculate the gauge size using the formula provided above. 4) Record the results and compare them to the required gauge size.

Understanding the Importance of Gauge Sizes in Manufacturing

Using gauge sizes in manufacturing has several advantages. Using gauge sizes ensures that all components of a product are the same size, which helps to reduce waste and improve the overall quality of the product. Additionally, using gauge sizes can help manufacturers save time and money, as they do not need to purchase multiple tools for measuring different materials.

However, there are also potential risks associated with incorrect gauge sizes. Incorrect measurements can lead to manufacturing defects or malfunctions, which can result in costly repairs or even injuries. Therefore, it is important to ensure that the correct gauge size is used when manufacturing products.

Conclusion

Gauge size is an important factor to consider when manufacturing products. This article has provided a comprehensive guide to understanding and measuring gauge size, as well as tips for choosing the right gauge size for your project. To ensure successful manufacturing processes, it is essential to understand how gauge size works and to use the correct gauge size for each project.

(Note: Is this article not meeting your expectations? Do you have knowledge or insights to share? Unlock new opportunities and expand your reach by joining our authors team. Click Registration to join us and share your expertise with our readers.)